Within the quickly evolving panorama of business expertise, three fascinating developments are intertwining to streamline processes, enhance effectivity, and cut back downtime. They’re retrofitting, distant management/monitoring, and energy metering – and collectively, they make for an excellent technique to improve and enhance current equipment, reaping all the advantages of linked issues and knowledge evaluation with out the massive funding of fully new gear.

- Retrofitting industrial equipment

Retrofitting industrial equipment entails updating current gear with fashionable expertise to reinforce performance and efficiency. It permits companies to increase the lifespan of their equipment whereas adapting to evolving business requirements and necessities.

- Distant monitoring and management

Distant monitoring and management allow companies to supervise their operations from wherever on the planet. This functionality not solely improves operational effectivity but additionally facilitates proactive decision-making and troubleshooting, finally lowering prices and downtime.

- Energy metering

Energy metering entails monitoring and analyzing vitality consumption. By monitoring energy utilization, companies can determine areas for optimization, cut back waste, and decrease vitality prices, contributing to sustainability efforts and bettering their very own backside line on the similar time.

Our newest demo showcases the seamless integration of those three essential elements right into a single resolution, utilizing Arduino expertise.

The demo intimately

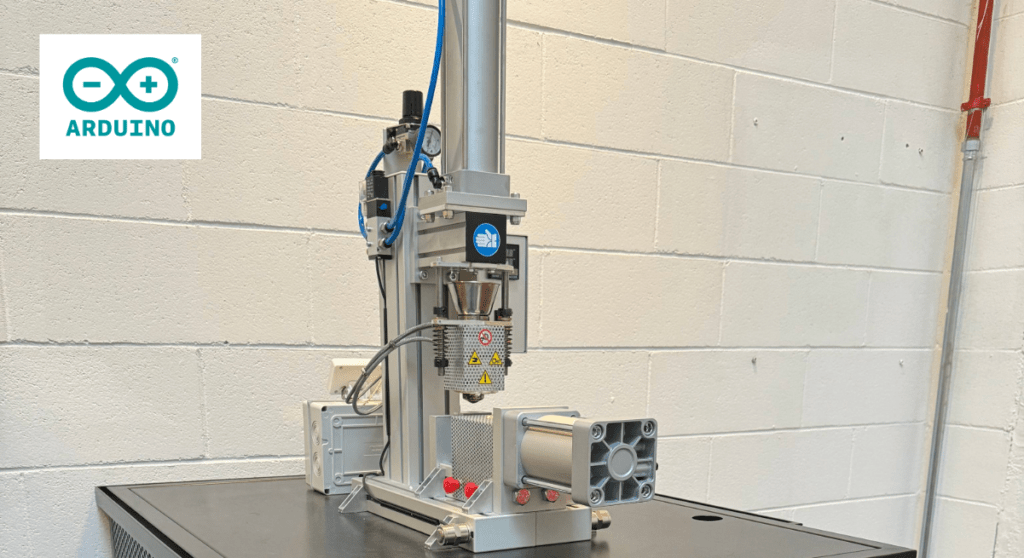

We targeted on retrofitting an injection molding machine – a typical piece of business gear – with superior automation capabilities. By changing the unique controller with the Arduino Opta WiFi micro PLC, we reworked the machine right into a linked gadget.

Now, integrating with the Arduino Cloud, customers can monitor and management the injection molding machine remotely by way of intuitive dashboards. This connectivity permits for real-time oversight of manufacturing cycles, efficiency metrics, and gear standing from wherever with an Web connection.

Moreover, the Arduino Opta WiFi is supplied with RS485 communication capabilities, enabling seamless integration with an exterior energy meter – in our case, a Finder mannequin. This offers precious insights into vitality consumption, manufacturing output, materials utilization, and gear well being.

The collected knowledge is then analyzed by devoted dashboards, providing details about operational effectivity and potential points. By leveraging this knowledge, companies can proactively schedule upkeep and repairs, minimizing downtime and optimizing manufacturing processes.

Retrofitting for a linked future

Many companies immediately can retrofit current equipment to embrace the advantages of connectivity and automation. Our demo offers a sensible instance of how frequent industrial gear can turn out to be smarter, extra environment friendly, and simpler to handle. From distant monitoring and management to energy metering and predictive upkeep, retrofitting affords a sustainable method to modernize industrial infrastructure.

Unlocking potential throughout industries

Furthermore, the flexibility of Arduino’s open-source ecosystem ensures that this resolution will be tailored and utilized to a variety of current machines and gear, enhancing their operation successfully – whether or not in manufacturing, logistics, or another business counting on equipment.

To be taught extra about how one can leverage Arduino expertise to improve your infrastructure and obtain tangible outcomes, contact us immediately. Allow us to provide help to unlock the complete potential of your industrial belongings with sensible, cost-effective options.

You may comply with any responses to this entry by the RSS 2.0 feed.

You may depart a response, or trackback from your individual web site.