The inexpensive {hardware} surpasses present high-end fashions and has the potential to result in an economical, at-home well being monitoring gadget sooner or later.

Credit:Picture: Courtesy of the researchers

Mass spectrometry is a strong approach for figuring out chemical parts in samples, which is beneficial for monitoring persistent sicknesses akin to hypothyroidism. Nonetheless, its excessive value, usually within the a whole lot of 1000’s of {dollars}, limits its use to laboratories, complicating the administration of persistent illnesses.

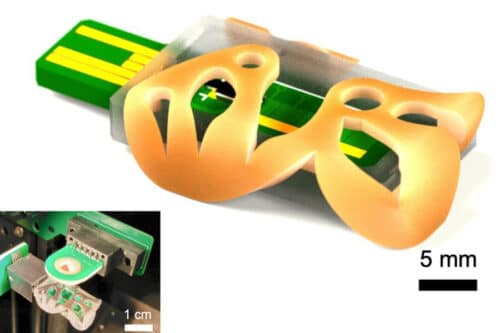

MIT researchers have made a breakthrough by 3D printing a low-cost ionizer, an important part of mass spectrometers, that outperforms present variations. This compact gadget could be mass-produced and built-in into spectrometers utilizing robotic meeting, making it more cost effective than conventional ionizers. The 3D printing course of permits for exact management over the gadget’s form and the usage of particular supplies to boost its efficiency.

Low-cost {hardware}

The researchers utilized 3D printing and strategic optimizations to create a low-cost electrospray emitter for mass spectrometry that surpasses the efficiency of state-of-the-art ionizers. They crafted the emitter from steel utilizing binder jetting, a course of that builds an object layer by layer by spraying a polymer-based glue by tiny nozzles onto a mattress of powdered materials. The thing is then heated to evaporate the glue and consolidate the powder. Following this, the emitters are electropolished to boost sharpness and coated with zinc oxide nanowires, which give the required porosity for efficient liquid filtration and transport.

Considering exterior the field

The workforce tackled the problem of liquid evaporation in electrospray emitters, which might trigger clogging, by turning it into a bonus. They designed their emitters as externally-fed stable cones with a selected angle that makes use of evaporation to regulate liquid circulate, leading to a sprig with a better ratio of charge-carrying molecules. In addition they redesigned the counter-electrode to stop arcing, permitting for a protected improve in utilized voltage, resulting in extra ionized molecules and improved efficiency. Moreover, they developed a low-cost printed circuit board with built-in digital microfluidics for environment friendly droplet transport.

The workforce plans to create a prototype combining their ionizer with a 3D-printed mass filter and is engaged on enhancing 3D-printed vacuum pumps, important for a compact mass spectrometer.