The TPM reference design makes use of a base station, LF initiator, and tire sensors to maintain autos protected and environment friendly, speaking by means of LIN and CAN networks.

The Tire Stress Monitoring (TPM) System is crucial for enhancing security and enhancing automobile effectivity. Correct tire stress is important for protected driving, as underinflated tires can result in harmful tire failures, resembling blowouts, doubtlessly inflicting accidents. The TPM system alerts drivers to such situations, permitting them to appropriate the problem promptly. Moreover, appropriate tire stress ensures that autos function with optimum gasoline effectivity. Underinflated tires enhance rolling resistance, which forces the engine to eat extra gasoline. By sustaining correct tire stress, the TPM system helps cut back gasoline consumption and extends the lifetime of the tires by stopping uneven put on. This not solely saves on gasoline prices but additionally reduces the frequency of tire replacements, additional emphasizing the significance of tire stress monitoring in fashionable autos.

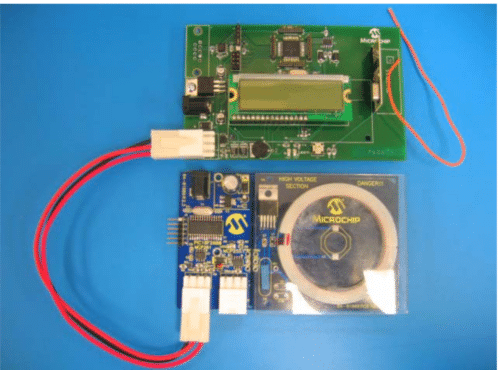

The reference design of TPM from Microchip consists of a base station, a low-frequency initiator, and tire sensors. The Base Station prompts the sensor modules in every tire utilizing the Low Frequency Initiator to collect knowledge on stress, temperature, and battery stage sequentially. This course of is facilitated over the LIN community, the place the Base Station sends instructions to the LF Initiator. Subsequently, the LF Initiator sends a wake-up problem to the tire sensor modules utilizing a 125 kHz ASK modulated sign. The Tire Sensor module’s 3-axis Analog Entrance Finish (MCP2030) verifies the problem and wakes the microcontroller from sleep provided that the preambles align. Following activation, the sensor module measures the stress and temperature, checks the battery standing, and transmits this knowledge again to the Base Station through a 433.9 MHz sign. The Base Station then shows the data on an LCD.

The Base Station, outfitted with a PIC18F4680 and together with MCP201 LIN Transceiver and MCP2551 CAN Transceiver, handles communications over LIN or CAN networks. The LF Initiator module makes use of a PIC18F2680 and likewise options these transceivers for sturdy knowledge communication. In the meantime, the Tire Sensor module constructed round a PIC16F684 microcontroller employs the MCP2030 AFE to detect the 125KHz sign and consists of analog sensors for correct stress and temperature measurements. This setup helps RF protocols (UHF and 125KHz), contributing to its low energy consumption and dependable sign detection. The pliability of this method makes it a strong selection for guaranteeing automobile security and effectivity throughout varied tire monitoring functions.

The module makes use of a microcontroller that’s chosen for its complete characteristic set, together with a CAN controller and a LIN-compatible EUSART, permitting it to interface effectively with in-vehicle networks. Moreover, the module incorporates a UHF receiver which options an AM super-regenerative compact hybrid module to seize decoded knowledge from an AM transmitter. This receiver presents excessive frequency stability throughout a broad vary of working temperatures and is strong in opposition to mechanical vibrations or handbook dealing with. It additionally features a laser-trimmed onboard inductor, eliminating the necessity for adjustable parts, thus simplifying the design and enhancing reliability.

Microchip has examined this reference design. It comes with a Invoice of Materials (BOM), schematics, and so forth. You will discover extra knowledge in regards to the reference design on the corporate’s web site. To learn extra about this reference design, click on right here.