From the combination of cutting-edge AI and IoT to improvements in miniaturisation and imaginative and prescient methods, delve into the long run the place these machines streamline manufacturing processes and redefine the effectivity and flexibility of meeting traces throughout industries.

Within the fast-paced world of producing, the place effectivity and precision are paramount, pick-and-place (PnP) machines have emerged because the unsung heroes of the meeting line. These subtle gadgets are instrumental in numerous industries, from electronics to meals packaging, embodying the spirit of innovation that drives fashionable manufacturing processes. However what makes these machines indispensable, and the way are they evolving to satisfy the calls for of an more and more complicated manufacturing panorama?

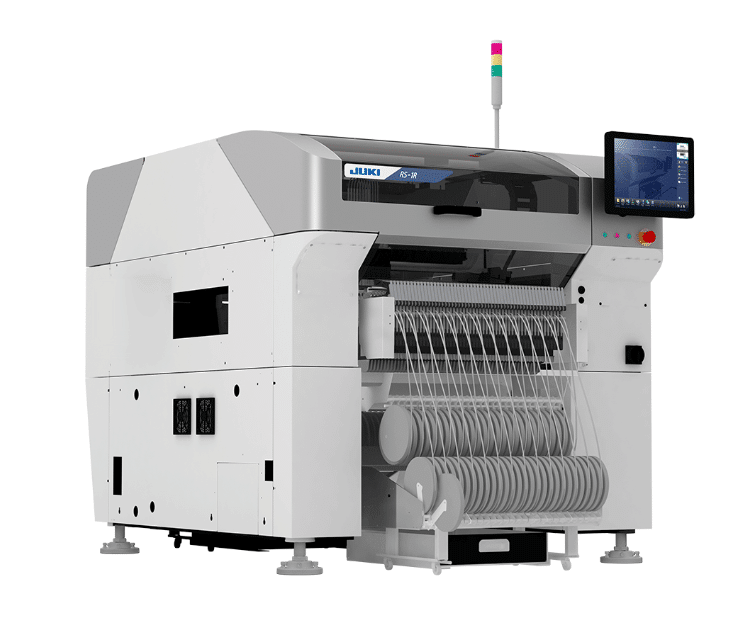

On the core of this evolution lies the problem of miniaturisation and the ever-present integration of electronics. As talked about by Shailendra Mathur, Enterprise Head and Product Supervisor (Different Power Options), MaximSMT, as parts grow to be smaller and manufacturing calls for soar, PnP machines are pushed to their limits, striving for extra unbelievable velocity, accuracy, and effectivity. However have you ever ever questioned how these machines preserve such excessive precision in inserting tiny parts onto PCBs or packing merchandise with unerring accuracy?

The search for optimum effectivity

A vital facet of enhancing manufacturing effectivity is decreasing setup and changeover instances. These often-overlooked durations can considerably impression a manufacturing line’s general effectivity. Each minute saved in these processes interprets into priceless manufacturing time. However how are producers minimising these ‘hidden’ downtimes?

Throughout a dialog with EFY’s Akansha Sondhi Gaur, Shreyansh Gupta, Supervisor and Gross sales Advertising, DJK emphasised that the verification course of ensures that each element is accurately positioned, aiming for zero unsuitable manufacturing. By integrating superior sensors and imaginative and prescient methods, machines can routinely detect and proper errors, considerably decreasing setup instances. Even a tiny rejection fee can have substantial monetary implications in a high-volume manufacturing.

How is the combination of IoT remodeling the way in which machines function and talk within the manufacturing ecosystem? Whereas {hardware} developments have their limitations, software program developments are revolutionising PnP know-how. Integrating synthetic intelligence (AI) and machine studying (ML) allows machines to study from patterns, predict upkeep wants, and optimise manufacturing processes. This shift reduces downtime and enhances general tools effectivity (OEE).

However what does the long run maintain for AI and ML in manufacturing? The transfer in direction of ‘black room know-how’—totally automated, robot-assisted manufacturing traces—minimises human error and will increase effectivity. The business is shifting in direction of extra environment friendly, error-free manufacturing by counting on robotics. The mixing of Business 4.0 requirements is creating an interconnected ecosystem the place machines talk and make data-driven selections. How are these developments shaping the way forward for manufacturing?