NORD drive options for the method {industry}

From 10 to 14 June 2024, NORD might be presenting a variety of merchandise at ACHEMA in Frankfurt am Important. The main target is on ATEX-compliant drive ideas for the method {industry} and the sturdy heavy-duty MAXXDRIVE industrial gear unit, particularly for agitator and mixer purposes. Additional focal factors on the commerce honest would be the new decentralised NORDAC ON/ON+ frequency inverters, the revolutionary DuoDrive geared motors and IE5+ synchronous motors in addition to the NORDCON APP with NORDAC ACCES BT. commerce guests can discover out extra about NORD’s wide selection of options on the commerce honest grounds in Frankfurt am Important in Corridor 8.0, Stand B52.

Whether or not within the chemical, pharmaceutical or meals industries: Firms that extract, transport or course of uncooked supplies require industry-specific, modern drive options. As a system provider, NORD affords matched drive programs consisting of substances unit, motor and drive electronics which can be tailor-made to the respective necessities of the shopper utility.

ATEX drives for explosion-protected areas Flammable gases and mud in processing industries create severe security dangers. NORD has a long time of expertise with fuel and mud explosion safety and affords notably sturdy electrical motors with powers from 0.12 to 200 kW particularly for this discipline of use. The explosion-protected electrical motors might be operated in class 2D or 3D mud atmospheres (zones 21 and 22) in addition to in class 2G or 3G fuel atmospheres (zones 1 and a pair of) and are authorised in keeping with ATEX and HazLoc. The dust-protected motors characteristic the ignition safety class “Safety by enclosure” (tD). Relying on the necessities, the motors within the fuel explosion safety model can be found within the following ignition safety lessons: elevated security

(e), pressure-resistant encapsulation (d/de) and non-sparking design.

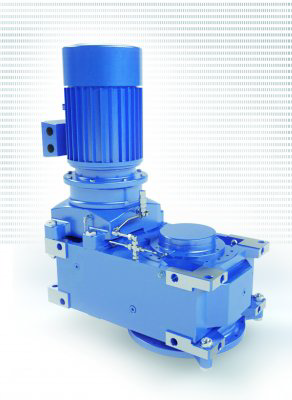

Industrial gear models for prime torque purposes NORD’s MAXXDRIVE industrial gear models energy heavy-duty purposes corresponding to agitators, mixers and grinders in meals or beauty manufacturing. The parallel and right-angle gear models cowl a pace ratio vary from 5.54:1 to 400:1 – and with a first-stage gear unit, even as much as 30,000:1. They characteristic:

• Excessive output torques from 15 to 282 kNm for dependable operation even below excessive circumstances

• Torsionally inflexible, one-piece UNICASE housing for an extended bearing life and environment friendly energy transmission

• Giant low-friction curler bearings for very excessive radial and axial load capacities and a protracted service life

• Excessive-precision axis alignment for assured quiet operating

For mixer and agitator purposes, the commercial gear models will also be outfitted with a SAFOMI-IEC

adapter:

• The adapter is out there for parallel gear models and in sizes 7 to 11, i.e. for max output torques from 25

to 75 kNm.

• The adapter is compact and easy in design and has an built-in oil enlargement quantity; oil tanks and hoses in addition to the radial shaft seal that’s topic to leakage and put on between gear unit and IEC cylinder are subsequently not required.

Decentralised drive electronics

The NORDAC ON frequency inverters are a part of the NORD modular system and might be optimally mixed with the producer’s motors.

• NORDAC ON was designed for purposes with asynchronous motors,

• NORDAC ON+ was designed for the mixture with extremely environment friendly IE5+ synchronous motors.

The inverters are designed for energy ranges from 0.37 to three kW.

Vitality-efficient IE5+ synchronous motors

The IE5+ motor era from NORD DRIVESYSTEMS ensures the best degree of effectivity and operational reliability, due to IE5+ expertise. The motors can be found as a TENV smooth-surface motor, as a TEFC motor with cooling fins and as an built-in DuoDrive motor. The latter combines a highefficiency IE5+ motor and a single-stage helical gear unit in a single housing. The IE5+ synchronous motors with motor efficiencies of as much as 95% can be found within the TEFC model with an influence of as much as 4.0 kW, within the TENV

model with as much as 2.2 kW and within the DuoDrive model with as much as 3.0 kW.

Cellular upkeep and commissioning

With the NORDCON APP for cell upkeep and commissioning of NORD frequency inverters, NORD allows the prognosis, evaluation, parametrisation and monitoring of the drive programs through a cell terminal system for service use. The NORDAC ACCESS BT is a Bluetooth stick that’s used immediately with the frequency inverter – this ensures handy cell entry to the drive knowledge whereas on the similar time entry management.

NORD will current its complete vary of options at ACHEMA in Corridor 8.0, Stand B52.