Just like the infrastructure for passenger automobiles, chargers might be wanted to cost industrial automobiles for a number of lots of of kWh throughout the driver’s lunch break. Delivering 500 kWh in lower than half-hour would require over 1 MW of charging energy.

Present high-power charging requirements embody energy ranges as much as 2.2 MW and might be anticipated to improve as much as 4.5 MW within the coming years.

Latest options for passenger automobiles, based mostly on fast-switching units like IGBTs or SiC-MOSFETs, goal energy ranges as much as 350 kW however merely scaling up this strategy might not the most effective resolution. Topologies and applied sciences used for comparable high-power DC purposes reminiscent of electrolysis are higher decisions by way of measurement, value, effectivity, availability, and reliability.

1. State-of-the-art Excessive-Energy DC-charging strategy

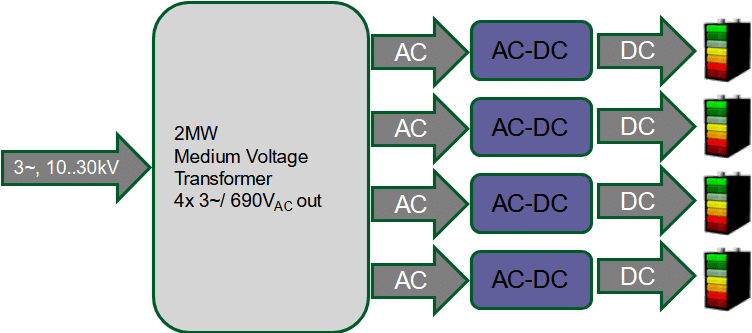

Many international locations around the globe have launched chargers that present 350 kW for passenger automobiles. With charging parks alongside important routes that supply 6-10 chargers, the ability can solely be offered from the medium-voltage grid by the use of transformers. A typical construction for such a setup is depicted in Fig 1.

.

Fig 1: Excessive-Energy Charger provided by way of medium-voltage transformer

Every of the chargers, respectively AC-DC-Converters, helps 350 kW by stacking models with decrease output energy.

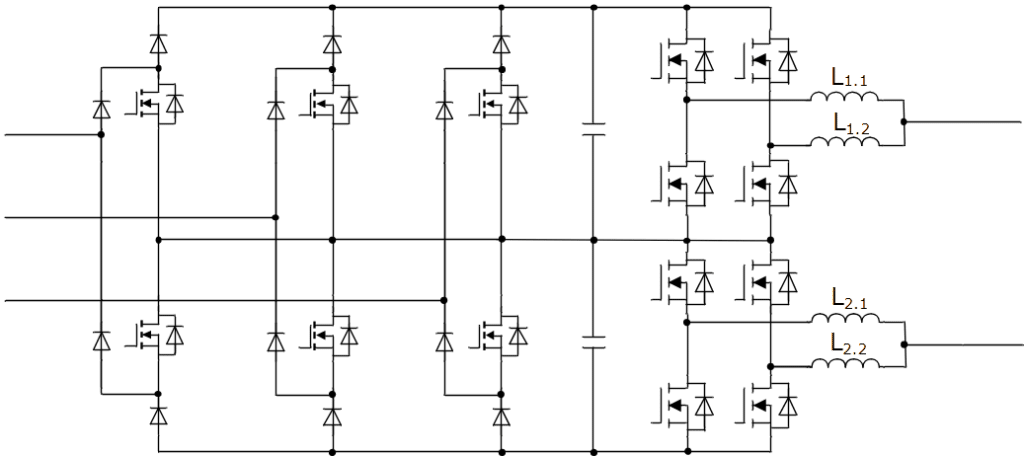

Normally, these subunits stay within the vary of 60 to 80 kW. A broadly used strategy consists of an enter stage with boost- and PFC-functionality, adopted by a DC-DC-converter in buck configuration to adapt the DC voltage to the battery’s necessities. A non-isolated and due to this fact extra environment friendly design is sketched in Fig. 2.

Right here, SiC-MOSFETs are applied to additional improve effectivity. To realize or exceed 60 kW of output energy at excessive effectivity, every MOSFET within the diagram consists of at the least 2 dies in parallel leading to using at least 28 MOSFETs in a single subunit.

To construct a single 350 kW AC-DC-converter, six of those models should be paralleled.

The effectivity of such a non-isolated converter construction utilizing SiC-based units is talked about to exceed 97% [1]. Although that is an achievement already, it additionally implies that every subunit contributes 1800 W of losses, summing as much as 10.5 kW for the whole setup.

Subsequently, liquid cooling turns into a compulsory prerequisite for this strategy.

2. Excessive-Energy Electrolysis

Electrolysis is a course of wherein bonded components and compounds are dissociated by the passing of an electrical present.

Electrolysis is used, for instance, to extract metals, or to supply substances that will be costlier or hardly attainable to extract by purely chemical processes. Examples of essential electrolysis processes are the extraction of hydrogen, aluminium, magnesium, chlorine, and caustic soda.

Lately, as a result of consideration given to inexperienced hydrogen manufacturing, electrolysis has turn out to be a outstanding subject.

State-of-the-art in electrolysis

The ahead voltage of a single electrolysis cell that separates water into hydrogen and oxygen is roughly 1.8-1.9 V, relying on the temperature and the chemical components used to reinforce the electrolyte. The Present densities within the electrolyte vary as much as 0.5 A/cm².

At 1000 A of DC-current, a cell that includes an space of 2000 cm² might be powered, producing roughly 1 kg of gaseous hydrogen per day.

The key similarities between electrolysis and battery charging come from {the electrical} settings.

The Prerequisite for an optimized course of in these two purposes is exactly managed DC voltages and currents. The voltage is utilized to a collection connection of cells whereas the person cell voltages add as much as the DC voltage. The distinction intimately lies within the single cell’s voltage degree and the correlating U-I-characteristic.

From chemical viewpoint, charging a battery is an electrolysis course of itself.

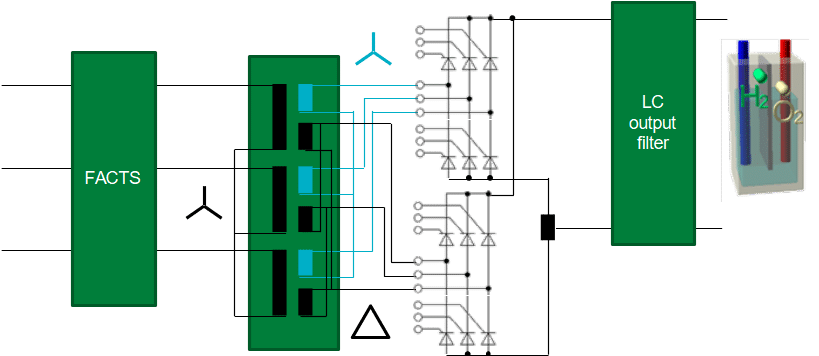

For many years, the dominating topology utilized in high-power electrolysis is the thyristor-based 12‑pulse rectifier as sketched in Fig 3.

The core elements are the transformer and the 2 unbiased B6C-rectifiers.

It can be crucial, that the 2 particular person 3-phase outputs of the transformer are phase-shifted by 30°.

Devoted transformers to attain this are the kinds Dy5Dd0 with a primary-winding scheme in delta-connection, in addition to sort Yy0Yd11 that provides a Y-structured primary-winding. In each circumstances, the secondary outputs of the 2 techniques have to be matched with regard of their voltage amplitude.

The 2 B6C bridges might be series-connected to assist larger voltages and thus a bigger variety of cells in series-connection to be powered.

Alternatively, the bridges might be paralleled to extend the present in a given variety of cells.

Main advantages of the topology embody a really low voltage ripple of lower than 3% when working close to the utmost output voltage and minimal impression on the first aspect as a result of solely harmonics 12 occasions the grid frequency seem.

Sometimes, the voltage is tailored in a slender band beneath the rated output. The instance features a 690 Vac output on the transformer which results in a most DC voltage of 975 V for every of the rectifier phases. Adapting the voltage in a spread to at least 780 V retains the ability issue cos(φ) bigger than 0.8 and thus in a regime that doesn’t want particular consideration with regard to reactive energy compensation. In electrolysis, this could simply be achieved by selecting a corresponding variety of cells within the collection connection.

To permit energy ranges to vary all the way down to 50%, reactive energy compensation on the medium-voltage-side are wanted. These symbolize an electrically and cost-efficient resolution to ensure the setup adheres to the person grid codes.

Being a single-stage AC-DC vitality conversion, the setup has a confirmed observe report of excellent effectivity, availability, and longevity. The thyristor-based designs have been in everlasting operation on website for many years and the press-pack units concerned have wonderful capabilities by way of power- and thermal biking efficiency.

Channelling 2 kA by means of thyristors in a B12C calls for an influence part just like the N1718NC200 [2].

An additional enchancment might be achieved by establishing such a construction in a so-called n+1 scheme. Right here, a second thyristor is added in every place. Though this sacrifices effectivity, it provides redundancy to the system. Presspack units supply the characteristic known as “brief on fail” and in case one thyristor fails, it fails brief. Because of the truth that the ahead voltage drop might be detected, upkeep might be preventively scheduled whereas the rectifier stays operational with no loss in efficiency.

3. Thyristor-based Excessive-Energy Charging

One vitality conversion stage is eliminated by altering from fast-switching units to a managed direct AC-DC-approach and using thyristors actually eliminates the switching losses. Each results in elevated effectivity, boosted by the non-linearity of the bipolar energy semiconductor.

From the N1718NC200’s datasheet, the ahead voltage might be extracted to be 1064 mV at 500 A, rising to 1148 mV at 1000 A. This represents an equal resistance of 1.15 mW solely. holds the associated on-state traits.

Evaluating the thyristor in use by PLECS-simulation reveals, that after ramping as much as IT=1000 A, the losses in every of the rectifiers’ semiconductors develop to 384 W. The simulated ramp-up consequence might be seen in Fig. 5.

With 384 W per thyristor, the twelve units solely contribute 4600 W of losses whereas the output energy is 2.5 MW. This means an effectivity of 99.8%, which is a key issue within the transition from liquid cooling to forced-air cooling.

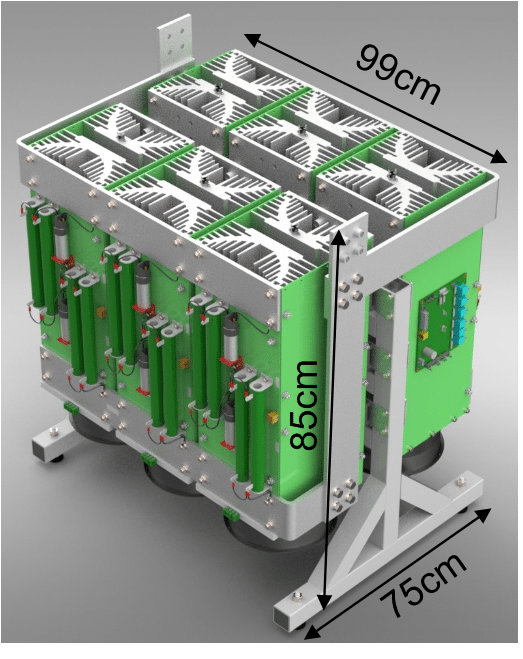

A stack containing the 2 unbiased B6C bridges was designed and constructed to judge mechanical options as nicely a measurement and materials content material; the rendering is depicted in Fig. 6.

Along with the wonderful effectivity, the burden, quantity, and complexity of the ultimate system are additionally vastly decreased.

4. Evaluating SiC-MOSFET and Thyristor as core elements in a 2.5 MW set up

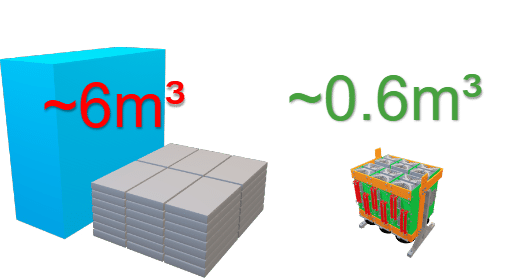

Fig. 7 is a comparability of the required elements with all elements drawn to the size.

The comparability in is predicated on the actual fact, {that a} SiC-MOSFET-based 60 kW system as described in suits into an industrial 19’’-rack and has dimensions [W/H/D] of 483 mm x 90 mm x 880 mm.

With 75 kW of losses, liquid cooling calls for a chiller to deal with that a lot thermal vitality. Primarily based on expertise, 1/3 of that energy is required on {the electrical} aspect to extract this warmth.

Thermal administration on the thyristor stack is proscribed to compelled air cooling utilizing six followers, every with 100 W.

An outline on additional essential parameters describing the two.5 MW-system is summarized in Desk 1.

Desk 1: Comparability of the 2 totally different options in numbers

| SiC-MOSFETs | Thyristors | |

| Nr. of subunits |

42 | 1 |

| Nr. of energy semiconductors |

>1100 | 12 |

| Nr. of AC connections |

126 | 3 |

| Nr. of DC connections |

84 | 2 |

| Weight | unknown | 370 kg |

| Constructed quantity | 6m³ | 0.6m³ |

| Connections for liquid cooling | 84 | – |

| Effectivity | 97% | 99.7% |

| Losses @2.5 MW throughput | 75 kW | 7.5 kW |

| Cooling energy | 25 kW | 0.6 kW |

A rise in effectivity by 2.7% might not seem like a giant distinction within the first place. it from a special perspective, this does imply there’s a 90% loss discount throughout the system. This in flip has a large impression on the appliance in {hardware} as a result of needed liquid cooling. It additionally closely impacts the operational value for the charge-point operators.

Contemplating initiatives like [3], concentrating on to arrange 1700 installations with MW-capable {hardware}, each energetic in addition to monetary losses resulting from inefficiency develop intolerably.

If every of the chargers operates 24/7 and handles three automobiles per hour, 10 minutes every to switch 400kWh, the vitality consumption and losses as given in Desk 2 consequence.

Desk 2: Evaluating SiC-MOSFET and Thyristor-based options concerning value of operation

| Liquid Cooling, SiC- MOSFET |

Compelled-Air cooling Si- Thyristors |

||

| Cooling | Energy per charger [kW] | 25 | 0.6 |

| Power per 12 months per charger [kWh] | 109500 | 2628 | |

| Power value per charger [€/year] @ 0.1€/kWh | 10950 | 263 | |

| Cash spent, 1700 chargers [€/year] | 18.615.000 | 447.1400 | |

| Operation | Losses, single cost [kWh] | 12.5 | 1.25 |

| Power misplaced in 1700 chargers per 12 months [kWh] | 558.450.000 | 558.450 | |

| Losses in 1700 chargers per 12 months [€] | 55.845.000 | 5.584.500 | |

| Cash saved per 12 months [€] | – | 64.510.972 |

As a aspect notice, there is also an environmental penalty as every kWh of electrical energy is burdened with a CO2 footprint. With about 0.5 kg CO2/kWh, nearly 280.000 tons of CO2-generation might be prevented.

These numbers develop quickly, if autonomous automobiles are thought of and the chargers utilization will increase past the 50% assumed on this state of affairs. If the output energy of the charger will increase to the utmost restrict given by the requirements, the identical applies.

Conclusion

Electrification of industrial quality automobiles is a compulsory step in direction of emission discount in visitors. Though the effectivity of electrical motors is considerably improved in comparison with their combustion-engine counterparts, striving for optimum effectivity within the supporting infrastructure turns into an essential a part of the sport.

At infrastructure scale, effectivity turns into an much more essential issue, as the quantity of vitality doubtlessly misplaced might have a destructive impression on the complete economic system. It’s to be famous that care ought to be taken to not merely scale up an present resolution however to construct the infrastructure based mostly on concerns that embody effectivity, availability, and longevity as nicely.

Intimately, this calls for to assessment all accessible choices to finally select probably the most appropriate one, even when that isn’t the latest, fancy or hyped one.

An effectivity beneath 100% is a transparent signal, that there’s room for enchancment.

References

[1] Infineon Applied sciences: Herausforderung Schnell-Ladung, Effiziente Gleichstromschnellladestationen mit Ladeleistungen bis 350kW im Good-Grid der Zukunft

(The Quick-Charging Problem, Environment friendly DC-Quick-Charging stations with charging energy as much as 350kW in future good grids) Freiburg, October 2019

[2] Knowledge sheet, N1718NC200, Challenge 4

[3] Daimler, Volvo and Traton plan $600 million truck-charging JV visited July 28, 2021

Writer: Dr. Martin Schulz, World Principal Software Engineer, Littelfuse

Dr. Martin Schulz joined Littelfuse in February 2021 as World Principal in Software Engineering. He’s answerable for energy semiconductors for electrical industrial automobiles, charging infrastructure, vitality storage techniques and industrial drive know-how. He’s an skilled in packaging and interconnect know-how in energy semiconductors in addition to in thermal administration of energy semiconductors. Martin Schulz has greater than 20 years of expertise within the subject of energy electronics and is a Senior IEEE-Member.

👇Observe extra 👇

👉 bdphone.com

👉 ultraactivation.com

👉 trainingreferral.com

👉 shaplafood.com

👉 bangladeshi.assist

👉 www.forexdhaka.com

👉 uncommunication.com

👉 ultra-sim.com

👉 forexdhaka.com

👉 ultrafxfund.com

👉 ultractivation.com

👉 bdphoneonline.com