Introduction

Electrical motors are pivotal in powering home goods and propelling large-scale business home equipment. The mechanical movement produced by motors is what makes them important in functions that require effectivity, reliability, and exact management over motion.

At its core, an electrical motor is a tool that converts electrical vitality into mechanical movement. Understanding the essential idea of an electrical motor is essential earlier than delving into the categories and particular functions. Electrical motors function based mostly on a basic precept of physics: electromagnetism. When an electrical present flows by means of a conductor (equivalent to a coil of wire), it generates a magnetic area.

If this conductor is positioned inside a bigger magnetic area, the interplay between the 2 fields generates a power, inflicting the conductor to maneuver. This movement is harnessed to carry out mechanical work, equivalent to rotating a fan. This motion is rotary in most motors, which means the conductor rotates inside a magnetic area. By fastidiously designing the motor’s elements, such because the rotor and the stator, engineers can management the velocity, course, and torque produced by the motor.

Electrical motors have an interesting historical past of improvement, beginning with the earliest types of motors within the 18th century. The journey of motor evolution is the best instance of humanity’s quest to harness electrical energy and remodel it into helpful mechanical energy.

However why did engineers and inventors really feel the necessity to experiment with completely different motor designs, like AC and DC, and ultimately department out into specialised motors?

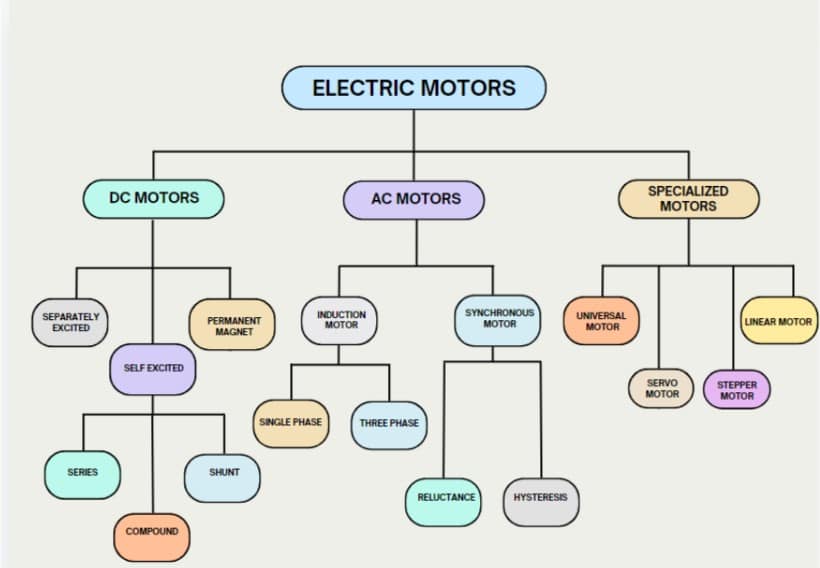

Kinds of Electrical Motors

Electrical motors have come a great distance, with their journey ranging from the DC motor. Early experiments in electromagnetism confirmed {that a} rotating magnetic area might energy mechanical units, making DC motors the primary sensible answer.

Nonetheless, that they had some drawbacks. DC motors used brushes and commutators, which wore out rapidly and wanted fixed upkeep. Additionally they weren’t nice for transmitting electrical energy over lengthy distances, resulting in important vitality loss.

As electrical networks expanded, AC motors grew to become extra widespread. AC was extra environment friendly for long-distance energy transmission as a result of it might simply change voltage ranges by way of transformers, making it splendid for large-scale distribution.

Nonetheless, whereas AC motors had been highly effective, not like their DC counterparts, they lacked positive velocity management and torque adjustment. This sparked additional innovation, as engineers realized that no single motor might meet each want.

Right this moment, we now have a variety of motors, every providing distinctive advantages relating to responsibility cycle, RPM management, and torque. Understanding their strengths and the way they function for particular functions is crucial.

Now, let’s discover the fascinating world of motor varieties, their functions, and the way they work.

DC Motor

Definition: Operates on direct present (DC) and converts electrical vitality into mechanical vitality.

Working precept: A current-carrying conductor in a magnetic area experiences a power that generates torque and causes the motor to rotate. The interplay between the magnetic area and the present flowing by means of the armature windings produces the rotation.

Software: Electrical automobiles, cranes, hoists, elevators, industrial equipment, and toys.

1.1. Individually Excited Motor

Definition: A DC motor the place the sphere winding is powered by an exterior unbiased supply, separate from the armature winding.

Working precept: The motor’s area and armature windings are fed by completely different energy sources. This permits exact management over each the magnetic area and the armature present, offering better flexibility in controlling velocity and torque.

Software: Precision management functions, high-performance industrial drives, and analysis tools. Precision management functions, high-performance industrial drives, and analysis tools.

1.2. Self-Excited Motor

Definition: A DC motor the place the sphere winding is linked on to the armature circuit and the motor itself offers the required excitation.

Working precept: The identical energy supply offers present for each the sphere and armature windings. Because the armature rotates, it induces a voltage within the area winding, which strengthens the magnetic area, and thus the motor generates torque.

Software: Followers, pumps, blowers, and industrial machines.

1.2.1. Collection Motor

Definition: A sort of self-excited motor the place the sphere winding and armature are linked in sequence.

Working precept: Because the similar present flows by means of each the sphere and the armature, the motor develops excessive torque at low speeds. Nonetheless, the velocity decreases with growing load.

Software: Cranes, hoists, and electrical locomotives.

1.2.2. Compound Motor

Definition: Combines the traits of sequence and shunt motors, with each sequence and shunt area windings.

Working precept: The motor has a sequence area winding for prime beginning torque and a shunt area winding to stabilize velocity. This mixture presents a stability between velocity regulation and excessive torque.

Software: Elevators, rolling mills, presses, and conveyors.

1.2.3. Shunt Motor

Definition: A DC motor the place the sphere winding is linked in parallel with the armature winding.

Working precept: The parallel connection ensures that the sphere present is almost fixed, offering constant velocity, even below various hundreds.

Software: Lifts, followers, conveyors, and pumps.

1.3. Everlasting Magnet

Definition: A DC motor the place the magnetic area is produced by everlasting magnets as an alternative of a area winding.

Working precept: Everlasting magnets create a relentless magnetic area, so the armature interacts with this area to supply rotation with out the necessity for an exterior area present.

Software: small units like toys, moveable electronics, battery-powered instruments, and home equipment.

AC Motors

Definition: Operates on alternating present (AC) to transform electrical vitality into mechanical vitality.

Working precept: The alternating present produces a rotating magnetic area within the stator, which induces present within the rotor, creating movement. AC motors can function synchronously or in induction.

Software: Industrial equipment, family home equipment, HVAC methods, and followers.

2.1. Induction Motor:

Definition: An AC motor the place the rotor is just not electrically linked however as an alternative induced by the stator’s rotating magnetic area.

Working precept: The rotating magnetic area generated within the stator induces present within the rotor, which causes the rotor to rotate at a velocity barely slower than the stator area.

Software: Pumps, followers, conveyors, and compressors.

2.1.1. Single Section Motor

Definition: An induction motor that operates on a single-phase AC provide.

Working precept: A single-phase present generates a pulsating magnetic area within the stator, which requires an auxiliary mechanism to start out rotation.

Software: Small family home equipment like followers, fridges, and washing machines.

2.1.2. Three Section Motor

Definition: A motor that runs on a three-phase AC energy provide.

Working precept: A rotating magnetic area is created by the three-phase provide, which induces present within the rotor, inflicting it to rotate. This motor is extra environment friendly and highly effective than single-phase motors.

Software: Industrial functions, equivalent to compressors, pumps, giant equipment, and elevators.

2.2. Synchronous Motor

Definition: An AC motor the place the rotor’s velocity matches the velocity of the rotating magnetic area within the stator.

Working precept: The rotor, utilizing everlasting magnets or electromagnets, locks in keeping with the rotating magnetic area produced by the stator, rotating at synchronous velocity.

Software: Excessive-precision functions, equivalent to robotics, timers, and conveyors.

2.2.1. Reluctance Motor

Definition: A synchronous motor that makes use of the phenomenon of magnetic reluctance to supply movement.

Working precept: The rotor aligns itself with the magnetic area produced by the stator to reduce magnetic reluctance, producing torque.

Software: Vitality-efficient processes, automation methods, and precision management functions.

2.2.2. Hysteresis Motor

Definition: A sort of synchronous motor that makes use of the magnetic hysteresis of supplies to function.

Working precept: The rotor develops torque by means of the lagging of magnetic domains inside the rotor materials relative to the stator’s rotating area, leading to easy and quiet operation.

Software: Precision tools like document gamers, clocks, and instrumentation.

Specialised Motors

Definition: Motors that function on distinctive ideas, usually utilized in specialised functions the place conventional AC or DC motors should not appropriate.

Working precept: These motors function utilizing particular mechanisms equivalent to linear movement, digital management, or a mix of each AC and DC ideas.

Software: Specialised equipment, robotics, and precision devices.

3.1. Common Motor

Definition: A motor that may run on each AC and DC energy.

Working precept: It’s a series-wound motor the place the identical present flows by means of the rotor and stator. This motor offers high-speed operation and works on each forms of present.

Software: Energy instruments, vacuum cleaners, and kitchen home equipment.

3.2. Servo Motor

Definition: A motor that gives exact management of angular place, velocity, and acceleration utilizing suggestions.

Working precept: A closed-loop system makes use of suggestions from an encoder or sensor to regulate the motor’s motion based mostly on the specified enter, permitting exact management over movement.

Software: Robotics, CNC equipment, and automation methods.

3.3. Stepper Motor

Definition: A motor that strikes in discrete steps, offering correct place management with out the necessity for suggestions.

Working precept: The motor rotates by transferring in fastened steps, the place every pulse despatched to the motor strikes it by one step, permitting for prime precision in positioning.

Software: 3D printers, CNC machines, and robotic arms.

3.4. Linear Motor

Definition: A motor that produces movement in a straight line moderately than rotational movement.

Working precept: The stator and rotor are laid out linearly. Because the magnetic area strikes alongside the stator, the rotor follows, creating linear movement.

Software: conveyor methods and actuators.

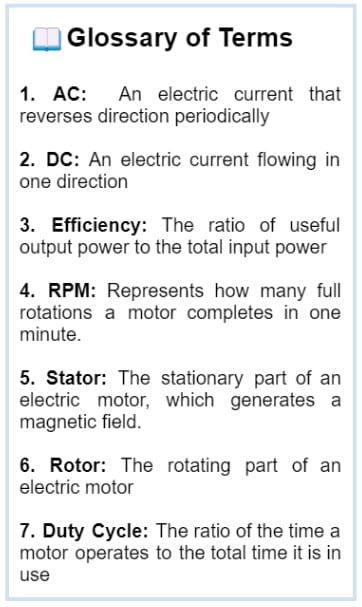

Understanding Motor Symbols

Sensible Functions of Electrical Motors

Electrical Followers

Electrical motors are a very powerful element that helps within the operation of electrical followers. Usually, these followers use small single-phase induction motors that present enough torque to spin the blades.

Electrical Automobiles

Electrical automobiles use highly effective electrical motors to drive their wheels, providing excessive torque, which is a major benefit over inner combustion engines. These automobiles usually use DC or AC motors, equivalent to everlasting magnet synchronous motors or induction motors. EV motors are recognized for his or her effectivity, quiet operation, and functionality to regenerate vitality by means of braking, additional growing their general vitality effectivity.

Wind Generators

When wind rotates the turbine blades, the motor (performing as a generator) converts the mechanical vitality of the rotating blades into electrical vitality. These motors are usually giant, high-efficiency synchronous turbines designed to deal with fluctuating wind speeds whereas sustaining secure energy output.

Robotics

Electrical motors, particularly servo and stepper motors, are basic to the operation of robotic arms and automatic equipment. These motors enable robots to carry out exact, managed actions in duties like meeting, welding, and materials dealing with. Robotics usually require motors with superior management capabilities, together with velocity, torque, and place suggestions.

Cellphone Vibration

Cellphone vibrations are powered by a tiny DC motor generally known as a vibration motor or vibrator motor. These motors are designed with an off-center weight hooked up to the motor’s shaft. When the motor spins, the uneven weight causes the cellphone to vibrate.

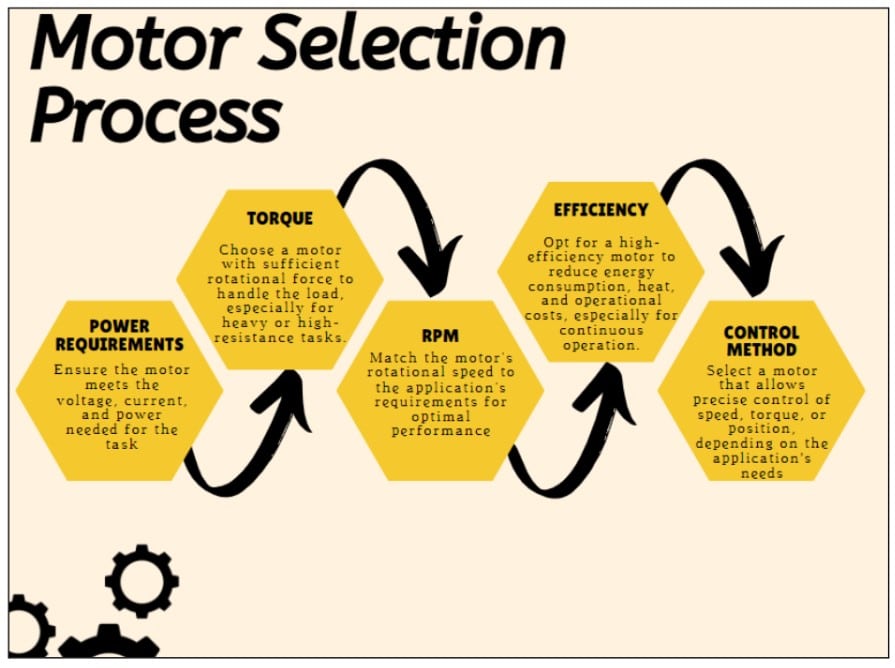

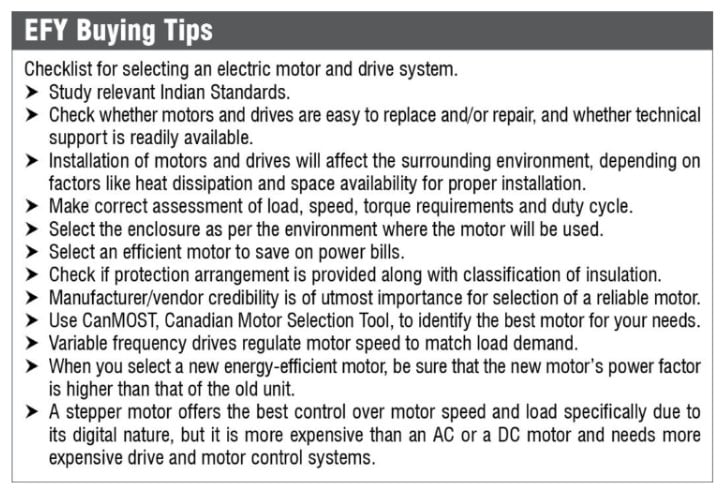

Motor Choice Information: What to Contemplate

For an in-depth information on choosing the appropriate motor, make sure you try our article on Deciding on an Electrical Motor and Drive System and Deciding on the Proper Motor for Your Design.

Drive Your Creativity: Electrical Motor Tasks to Strive

It enhances your hands-on abilities in circuit design and troubleshooting, making it splendid for hobbyists within the RC and robotics fields.

- Water Pump Controller: This thrilling challenge is an easy water pump controller circuit that regulates the water stage in an overhead tank.

It makes use of a step-down transformer, a 24V AC double-changeover relay, two floats, and two micro switches to effectively management the pump.

FAQs (Folks Additionally Ask)

What’s the distinction between AC and DC motors?

Ans. AC motors run on alternating present, whereas DC motors run on direct present. AC motors are extra generally utilized in industrial functions, whereas DC motors are sometimes utilized in units requiring exact management like electrical automobiles.

Which motor is greatest for electrical automobiles?

Ans. Brushless DC motors (BLDC) are usually most well-liked for electrical automobiles resulting from their excessive effectivity and low upkeep.

What’s the benefit of utilizing a brushless motor?

Ans. Brushless motors provide larger effectivity, require much less upkeep, and have an extended lifespan as a result of they eradicate the friction and put on related to brushes in conventional motors.

What’s a stepper motor, and the place is it used?

Ans. A stepper motor is a sort of DC motor that strikes in discrete steps, making it splendid for exact management in functions like 3D printers and robotics.

What’s the distinction between a synchronous motor and an induction motor?

Ans. A synchronous motor rotates at a velocity that’s synchronized with the availability frequency, whereas an induction motor operates barely slower resulting from slip.

Can electrical motors be used for regenerative braking?

Ans. Sure, many electrical motors, particularly in electrical automobiles, can be utilized for regenerative braking, the place the motor converts kinetic vitality again into electrical vitality to recharge the battery.

👇Comply with extra 👇

👉 bdphone.com

👉 ultraactivation.com

👉 trainingreferral.com

👉 shaplafood.com

👉 bangladeshi.assist

👉 www.forexdhaka.com

👉 uncommunication.com

👉 ultra-sim.com

👉 forexdhaka.com

👉 ultrafxfund.com

👉 ultractivation.com

👉 bdphoneonline.com