Lawrence Livermore Lab develops a silicone-based 3D-printed options for electrostatic discharge safety for digital parts.

Analysis crew from Lawrence Livermore Nationwide Laboratory (LLNL), California have engineered an progressive electrostatic discharge (ESD) safety answer by 3D printing, aiming to safeguard delicate digital parts from static harm. By utilizing a method referred to as direct ink writing (DIW), the crew has created silicone-based foams that defend electronics from dangerous voltage discharges, serving to to cut back potential element failures, monetary losses, and office dangers. This improvement could possibly be a game-changer for industries the place ESD safety is vital, resembling chemical and electronics manufacturing.

3D printing is a flexible manufacturing technique that enables exact management over the printed materials’s construction, making it best for purposes that demand customised mechanical properties. The analysis crew’s course of particularly allows the creation of mobile foams with intricate pore architectures that had been designed to soak up and evenly distribute stress throughout a element. This resilience is crucial for stopping deformation and mechanical harm, particularly when delicate circuit boards and digital parts are topic to sudden impacts or stresses. Potential adopters embrace producers in electronics, robotics, and medical machine fields the place tools typically encounters static and mechanical dangers.

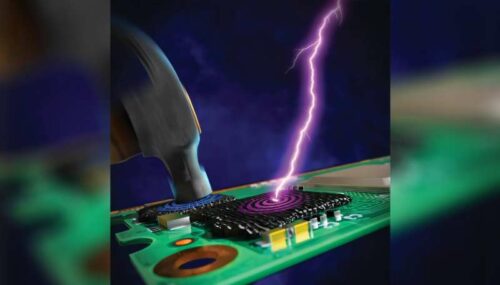

Key to this innovation is the crew’s use of direct ink writing (DIW), a specialised 3D-printing approach that extrudes a paste layer-by-layer to construct three-dimensional varieties. By leveraging DIW, the LLNL crew may print a singular silicone resin formulation that features carbon nanotube (CNT) concentrates and rheological modifiers. These components enable the construction to attain the mandatory conductivity for ESD safety whereas sustaining the elasticity and sturdiness wanted to face up to impacts, resembling these demonstrated by putting the printed construction with a hammer. The CNTs inside the resin act as conductive pathways to dissipate static electrical energy, whereas the rheological modifiers assist obtain the specified print high quality and structural precision.

Silicone resins are extremely fitted to ESD purposes because of their low volatility, thermal stability, and elasticity, all of which make them best for wearable tech, mushy robotics, and different superior engineering fields. The analysis crew’s 3D-printed silicone defend is utilized instantly onto circuit boards, performing not solely as a static guard but additionally as a cushioning layer that protects towards bodily harm. This dual-purpose safety has promising purposes for electronics in specialised tools utilized in robotics, medical units and extra.

Whereas additional refinements are anticipated, the present formulation successfully meets ESD safety wants. With continued developments, this know-how could pave the best way for brand new protecting options in electronics, enabling safer and extra resilient parts for business purposes

👇Comply with extra 👇

👉 bdphone.com

👉 ultraactivation.com

👉 trainingreferral.com

👉 shaplafood.com

👉 bangladeshi.assist

👉 www.forexdhaka.com

👉 uncommunication.com

👉 ultra-sim.com

👉 forexdhaka.com

👉 ultrafxfund.com

👉 ultractivation.com

👉 bdphoneonline.com