Bypassing Earth’s limitations, space-based microfabrication is rising to redefine semiconductor manufacturing. What provides the benefit regardless of challenges in supplies and processes?

What if semiconductors had been manufactured in outer house? This course of, also referred to as microfabrication, includes creating miniature constructions on the dimensions of micrometres or smaller. This method is essential for producing built-in circuits (ICs) on the coronary heart of contemporary electronics.

However microfabrication on Earth has its personal set of hurdles. Regardless of the abundance of uncooked supplies, international locations usually battle to ascertain their self-sufficiency on this discipline and search outsourcing. Apart from authorities help, expert labour, and competitors within the trade, Earth’s gravity and environmental challenges persist.

In that case, what distinction will house make? Initially, the price of transporting uncooked supplies to house shall be excessive, making the method costly. Nevertheless, the intention is to enhance the capabilities of those specialised sectors, in the end driving prices down and making it extra inexpensive in the long term. However how?

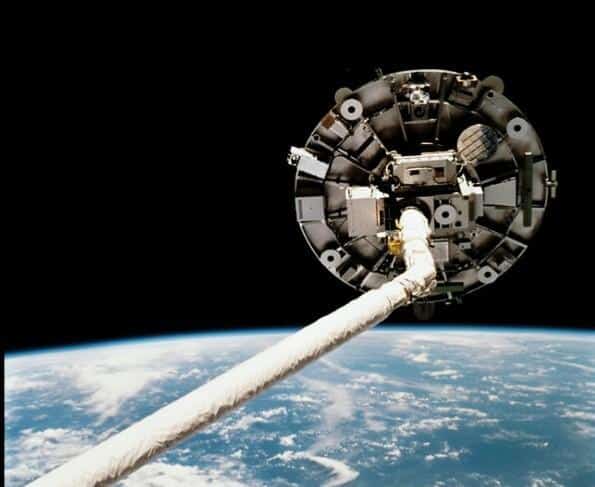

Manufacturing semiconductors in orbit provides important potential, opening up alternatives throughout a number of industries. With its low gravity and vacuum atmosphere, house gives a novel setting that would result in the manufacturing of high-quality, ultra-efficient chips—ranges of precision and high quality which can be merely unattainable on this earth. Given these benefits, it’s not shocking that we may even see many factories in house quickly.

Area factories appear to be on the rise

This may sound like one thing straight out of a science fiction novel, however a British firm is already planning to make it a actuality. This yr, Area Forge, a UK-based agency, eyes to launch small, washing machine-sized modules into low Earth orbit, roughly 500-800km above the floor, the place gravity is weaker, however retrieval stays possible. This atmosphere might simplify the manufacturing of uncooked supplies for semiconductor laptop chips, benefiting manufacturing processes similar to 3D printing.

Semiconductor manufacturing in house yields extremely pure crystal constructions. The house successfully permits the crystals to mix higher with fewer pollution. Larger crystal purity means the chips will produce much less waste warmth. This protects tens of millions of rupees when operated. Additional power utilization could be diminished by as much as 60%.

Area Forge is exploring various supplies, similar to gallium nitride (GaN). Your complete chip won’t be made in house; solely the uncooked materials shall be made. However how a lot possible is that this course of?

Why house?

Current normal terrestrial fabrication strategies are tough to adapt to the microgravity and vacuum atmosphere of house, as they’re optimised for the sources out there on Earth—water, energy, air stress, and gravity. To deal with this, an alternate microfabrication course of has been developed that utilises a vacuum atmosphere, which might substitute the moist processes sometimes used on Earth. This strategy not solely saves on tools dimension and consumables but additionally reduces cycle occasions.

Analysis has proven that by creating new, dry processes which can be appropriate with a vacuum, it’s each technically and economically possible to manufacture semiconductor units in orbit. This mixed effort holds the potential to ship business semiconductor constructions. Area itself is taken into account a super atmosphere for a lot of semiconductor processes, similar to semiconductor becoming a member of by atomic adhesion, fabrication of skinny movies of diamond and amorphous silicon alloys, CVD processes, manufacturing of super-minute grains, mild aspect evaluation by means of secondary ion mass spectrometry (SIMS), and anti-proton era utilizing laser accelerators.

Benefits that unlock areas’ potential

Setting friendliness! Manufacturing semiconductors in house will assist cut back carbon emissions whereas producing high-quality chips, because the ultra-low ambient stress in house—10 trillion occasions decrease than on Earth—removes contamination points and eliminates the necessity for multi-stage pumps. This know-how additionally brings appreciable value financial savings to purposes like 5G telephone masts, radar techniques, and electrical automotive charging. For example, many chips in 5G towers at the moment function at simply eight per cent effectivity, however changing them with space-made chips might triple their efficiency. Moreover, the method permits for the expansion of large-diameter crystals and the creation of nano-flat ribbon constructions. With zero carbon emissions, no water use, and no poisonous chemical substances, space-based microfabrication holds thrilling potential. Radiators dealing with the chilly of house also can obtain temperatures close to absolute zero, enabling ultra-fast curing with out cryogenic processes.

Redefining know-how

The purposes of space-based semiconductor manufacturing are huge and embody supplies like GaN, GaN on diamond, gallium arsenide (GaAs), and silicon carbide (SiC). These applied sciences have important potential to be used in space-based microsensors, photo voltaic cells, and radiation detectors, amongst different superior purposes.

However the challenges…

Nevertheless, there are a number of limitations too. The price of sending tools to orbit is substantial, making the preliminary funding excessive. Moreover, establishing and sustaining a producing facility in house presents important logistical challenges, requiring advanced planning and sources. The tough circumstances of house, similar to the shortage of ambiance and publicity to intense radiation, additionally pose dangers to tools, necessitating superior security measures and shielding to guard the know-how.

Apart from, important complexities persist in semiconductor manufacturing, notably in crystal progress, wafer processing, epitaxial progress, and circuit patterning. Moreover, creating next-generation carbon composite supplies, similar to nanocarbon-infused metals and alloys, in low Earth orbit (LEO) utilizing an electro-co-deposition technique to enhance the Worldwide Area Station’s (ISS) capabilities presents further hurdles.

Remaining ideas

The prospect of producing chips in house represents a paradigm shift within the tech trade, with the potential to redefine the capabilities of digital units. Area Forge’s pioneering efforts on this discipline are poised to open new frontiers in semiconductor know-how, providing unparalleled efficiency and reliability. Because the know-how continues to evolve, the affect of space-based chip manufacturing on numerous industries is anticipated to be transformative, ushering in a brand new period of innovation and progress.

👇Comply with extra 👇

👉 bdphone.com

👉 ultractivation.com

👉 trainingreferral.com

👉 shaplafood.com

👉 bangladeshi.assist

👉 www.forexdhaka.com

👉 uncommunication.com

👉 ultra-sim.com

👉 forexdhaka.com

👉 ultrafxfund.com

👉 bdphoneonline.com

👉 dailyadvice.us