Sensible brake management and diagnostics for servo drives and robotics improve security, reliability, and effectivity by changing standard strategies and stopping accidents.

The necessity for sensible brake management and diagnostics in servo drives and robotics is paramount resulting from their important function in making certain security, efficiency, and effectivity. Sensible brake management prevents accidents by partaking brakes throughout energy failures or emergencies and adheres to security requirements, lowering legal responsibility. Diagnostics allow early fault detection, enhancing reliability and minimizing downtime. These programs optimize energy utilization, making certain exact management, clean operation, and decreased operational prices. Moreover, sensible brake management programs facilitate predictive upkeep, integrating seamlessly with different programs and providing scalability for numerous industrial purposes. Sensible brake management and diagnostics reference design for servo drives and robotics from Texas Devices (TI) addresses the difficulty.

Variable velocity drives are extensively utilized in purposes comparable to robotics and pc numeric management (CNC) machines, the place security is a big concern as a result of fixed presence of holding and movement controls involving people. Current developments in drives with built-in security options have changed standard strategies like standstill and velocity displays, restrict switches, place cameras, and contactors, considerably enhancing system reliability. Automated manufacturing poses important risks, notably from gravitational forces throughout vertical actions within the occasion of an influence or brake failure. The “protected brake management” (SBC) perform ensures protected brake operation, stopping suspended hundreds from falling and avoiding unintended motion in CNC machines resulting from exterior forces.

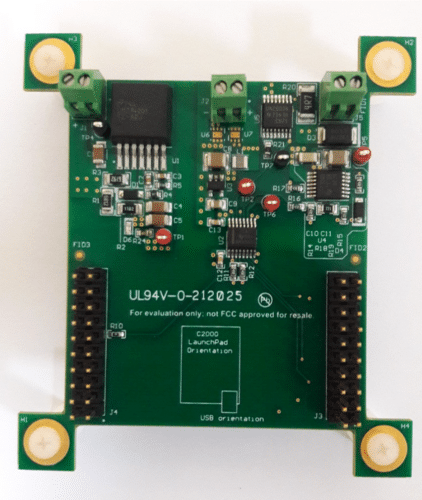

The reference design gives protected brake management for servo drives in line with IEC EN 61800-5-2, utilizing two-channel output indicators to regulate an exterior holding brake. The brake latches when energy is reduce off and releases when voltage is utilized to the coil. That is managed by turning on and off sensible digital load switches that energy the coil. The design additionally consists of diagnostic options to detect faults, guarantee protected operation and scale back energy consumption on the brake output. The C2000 LaunchPad generates the brake management indicators and performs diagnostic features.

It options twin change management to reinforce protected operation and consists of self-diagnostics for open load detection and overcurrent safety. Moreover, it presents high-side change failure detection, speedy utility of the holding brake by rapidly lowering the holding brake present, and optionally available voltage discount on the holding brake output to lower energy consumption.

Security brakes function in opposition to a spring utilizing a quiescent present; if the present is interrupted, the brake engages. Management modules typically function an influence discount functionality to reduce power consumption and brake heating when the brake is launched. Holding and repair brakes are generally used on axes with suspended hundreds, with the SBC perform controlling the holding brake as soon as the axis is stationary.

TI has examined this reference design. It comes with a invoice of supplies (BOM), schematics, meeting drawing, printed circuit board (PCB) structure, and so on. You could find extra knowledge in regards to the reference design on the corporate’s web site. To learn extra about this reference design, click on right here.

👇Observe extra 👇

👉 bdphone.com

👉 ultraactivation.com

👉 trainingreferral.com

👉 shaplafood.com

👉 bangladeshi.assist

👉 www.forexdhaka.com

👉 uncommunication.com

👉 ultra-sim.com

👉 forexdhaka.com

👉 ultrafxfund.com

👉 ultractivation.com

👉 bdphoneonline.com